In-depth analysis of "new infrastructure", how much demand for non-ferrous metals?

Release date:2020-05-27 Reading times:2299

At the beginning of 2020, Faced with the impact of COVID-19, China's economic growth is facing great pressure. Recently, many provinces, autonomous regions, and municipalities have launched a list of tens of trillions of investment plans. As of March 10, 25 provinces, autonomous regions, and municipalities have announced their future investment plans, with a total investment of 49.6 trillion yuan in 22,000 projects.Among them, the total planned investment in 2020 is 7.6 trillion yuan. Infrastructure investment not only plays an important role in underpinning the economy under counter-cyclical regulation, but also "new infrastructure" has become a new way to open up infrastructure investment in the future, and has become a hot spot for market attention.

The concept of "new infrastructure" was first proposed at the Central Economic Work Conference in December 2018, and the positioning of new infrastructure such as 5G, artificial intelligence and industrial Internet was clarified. In 2020, with the outbreak of COVID-19, the importance of new infrastructure has been significantly increased and the deployment has been further deepened. The Standing Committee of the Political Bureau of the CPC Central Committee has proposed the issuance of investment support policies for new infrastructure such as information networks. The Standing Committee of the Political Bureau of the CPC Central Committee has repeatedly emphasized the acceleration of the construction of new infrastructure such as 5G networks and data centers. Many provinces, autonomous regions and municipalities have made 5G network construction an investment priority in 2020. The official government has also officially identified seven major areas of "new infrastructure" : 5G infrastructure, ultra-high voltage, intercity high-speed rail and urban rail transit, charging piles for new energy vehicles, big data centers, artificial intelligence, and industrial Internet.

For the non-ferrous metal industry, new infrastructure projects are significantly more dependent on copper and aluminum and other non-ferrous metals than traditional infrastructure projects.For example, intercity high-speed railways and urban rail transit need to lay copper cable contact lines, UHV requires a large number of aluminum cables, transformers, and galvanized power fittings, 5G base station construction requires copper foil, and new energy vehicles and charging piles consume significantly more copper,big data centers and other projects require a considerable amount of electronic components.Then we will look at the impact on non-ferrous metals from various areas of the new infrastructure.

1. Intercity high-speed railway and urban rail transit

High-speed railway has put forward higher requirements on the strength, fatigue performance, lightweight and manufacturability of new materials, and non-ferrous metals are widely used in high-speed railway projects due to their unique properties. Among them, aluminum alloy has low density and good mechanical properties, and is mainly used in the stressed components, car bodies, as well as decorative and thermal insulation materials of high-speed railway. At present, aluminum alloy material has been widely used in domestic high-speed railway carriages. Industry experts pointed out that the speed of more than 300 kilometers per hour high-speed train body must use lightweight aluminum alloy material, more than 350 kilometers of train cars except chassis all use aluminum profiles. In addition, copper cables are mainly used for the overhead contact network laying on the upper end of locomotives due to their characteristics of large flow capacity, high corrosion resistance and good ductility. Electrical equipment such as substations and transformer stations along the way also require a large number of copper products. Similarly, urban rail transit, such as subway and tram, use a large number of metal materials, the laying of the power grid and the construction of the car body are inseparable from the support of copper cables and aluminum alloy profiles.

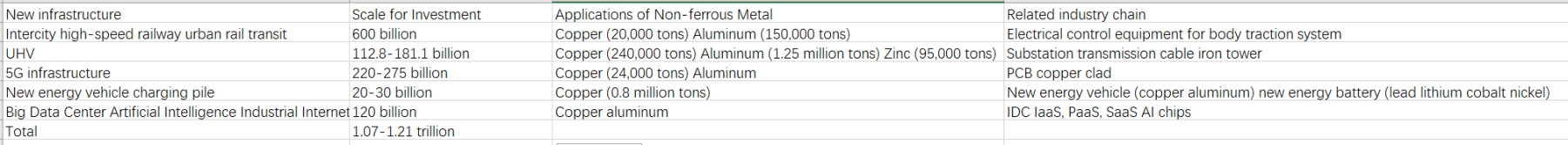

According to the use of special bond funds and statistics from the National Development and Reform Commission, the investment scale of intercity high-speed railway and urban rail transit is expected to be around 600 billion yuan in 2020. It is expected that by 2020, more than 4,000 kilometers of new railway lines will be put into operation, including 2,000 kilometers of high-speed railway and 1,200 kilometers of new subway lines. According to this preliminary estimate in 2020 high-speed rail and subway construction will need about 150,000 tons of aluminum, copper consumption will be about 20,000 tons.

2. UHV

State Grid has worked out the Pre-work Plan for UHV and Inter-provincial AC-DC Projects of 500 kV and above in 2020, and it is clear that it will accelerate the approval and pre-feasibility study of uHV projects within this year such as Nanyang - Jingmen - Changsha Project. Mao Weiming, chairman of State Grid Corporation, said that the company's uHV construction project has a clear investment scale of 112.8 billion yuan, which can drive social investment of 223.5 billion yuan, and the overall scale of nearly 500 billion yuan. State Grid Corporation said in a press release on March 14 that it invested 181.1 billion yuan in uHV construction projects in the whole year.

The transmission cables of UHV grid projects mainly use steel-cored aluminum strand, which is the reinforced wire with single or multi-layer aluminum strand stranded outside the galvanized steel core. The steel "core" is inside, and the aluminum wire is twisted around the steel core outside.The steel core mainly plays a role in increasing strength, and the aluminum strand mainly plays a role in transmitting electricity, which is mainly used in overhead transmission lines. It is estimated that the transmission cable accounts for about 23% of the UHV investment, and the aluminum content of steel-cored aluminum strand is about 67%. According to the average aluminum price in 2019 and the 112.8 billion UHV projects in 2020, the UHV projects in 2020 are expected to promote at least more than 1.25 million tons of aluminum consumption.

Copper cables are not used in network laying in UHV projects, but a certain amount of copper will be used in substation construction and some electrical equipment, such as copper clad steel ground grid laying, transformer, converter valve, GIS and other electrical equipment installation. According to the calculation, excluding the iron tower and infrastructure construction in the station, the investment of UHV equipment accounts for about 40%, and about 20-30% of these core equipment contains copper. Therefore, we can roughly estimate that in 2020, the uHV project of 112.8 billion yuan will provide about 240,000 tons of copper consumption.

In addition to copper and aluminum, galvanized steel is mainly used for anti-corrosion coating of uHV transmission tower and its supporting line fittings, such as galvanized steel strand, etc. Because the transmission line tower products are mainly used in the field environment, they are easy to corroded and rusting because they have to withstand various high temperature, hot summer, cold and frost weather. The oxidation corrosion on the surface of the tower can be reduced by galvanizing, and the service life of the tower can be improved. At present, hot dip galvanizing technology is widely used in Chinese iron tower enterprises, which can effectively improve the corrosion resistance and service life of iron tower. In UHV construction, the investment of transmission tower accounts for about 16%. It is estimated that the zinc consumption of galvanized tower is about 85KG/T, so it is expected that UHV will drive the zinc consumption of about 95,000 tons.

3. 5G infrastructure

In order to meet the Ministry of Industry and Information Technology's requirement for full 5G network coverage and accelerate the commercialization of 5G in China, the three major operators have proposed the goal of completing 550,000 5G base stations by 2020, among which China Mobile plans to target 300,000 and China Unicom and China Telecom plan to jointly build 250,000. As of early February, the three major operators had opened 156,000 5G base stations across the country. On March 6, China Mobile announced the centralized procurement of 5G wireless network equipment in the second phase of 2020, involving the acquisition plan of 5G base stations in 28 provinces, with a total of 232,000. According to the average cost of each base station is about 400,000-500,000 yuan, the total investment scale of 5G base station is about 220-275 billion yuan.

The application of copper in the construction of 5G base station is mainly focused on the copper clad plate (CCL) in printed circuit board (PCB), and copper foil is the key material to manufacture the copper clad plate. The market size of PCB and copper-covered plate in 5G era will be several times that of 4G, and the consumption of copper foil is expected to increase greatly in 2020, but the production of copper foil is mainly difficult in technology, and the consumption of copper is very small. According to the calculation, PCB value accounts for 5% of 5G base station, copper-clad board accounts for 30-40% of PCB cost, copper foil accounts for 30-50% of copper-clad board cost, copper foil processing cost is 30,000-45,000 / ton, fine copper to copper foil loss rate is 10%, and the copper consumption of copper-clad board required by 5G base station in 2020 is about 24,000 tons.

In addition to copper, a certain number of other metal products will be used in the construction of 5G base stations, such as aluminum electrolytic capacitors and high-end aluminum alloys.

4. New energy vehicle charging pile

The new energy vehicle industry has always been the pain point of charging pile matching and low cost performance. In 2019, the charging pile market developed rapidly. As of December 2019, the cumulative ownership of public and private charging piles was 1.219 million, with a year-on-year growth of 50.8%. The cumulative sales volume of new energy vehicles reached 4.2 million, and the car-pile ratio was 3.4:1. The penetration rate was still significantly behind the 2015 "Guide to the Development of Electric Vehicle Charging Infrastructure (2015-2020)" plan, which is 1:1 truck pile ratio.According to the development goal set by the country, the total number of charging piles in China will reach 4.8 million in 2020. It is expected that 373,000 new private ac charging piles will be added in 2020, and the number of private AC charging piles will reach 1.076 million. In terms of public charging piles, 156,000 and 12,000 public charging stations are expected to be added. Although the new energy automobile industry is in a painful period under the pressure of economic downturn and subsidy decline, the charging pile market is still in the process of rapid development, with rapid growth supported by the new infrastructure concept.

It is understood that the charging pile charging mode is divided into AC and DC, and the amount of copper is about 8KG and 60KG respectively. The amount of copper used in the household charging pile is about 2KG/ unit. Therefore, it can be estimated that the charging pile market will provide nearly 10,000 tons of copper consumption in 2020. Although this amount is small compared with China's annual output of tens of millions of tons, from another perspective, the gradual improvement of charging pile facilities will greatly improve the willingness to consume new energy vehicles.

According to the data, the average copper consumption of a hybrid vehicle is 60KG, and the copper consumption of a pure electric vehicle is 80KG, which is twice or even three times higher than the copper consumption of a traditional vehicle of 28KG. The average aluminum consumption of new energy vehicles is estimated to be 141.5KG (128.4KG for pure electric vehicles and 179.6KG for hybrid electric vehicles). In the future, the unit aluminum consumption of pure electric cars can reach 283.5KG, while the average aluminum consumption of traditional fuel vehicles is only 118.7KG. In the current Chinese automobile industry, the proportion of new energy vehicles is only about 5%. According to the calculation of 25.721 million and 25.769 million automobile production and sales completed in 2019, the proportion of new energy vehicles will increase by one percentage point, the consumption of copper will increase by 13,000 tons, and the consumption of aluminum will increase 42,000 tons.

At the same time, the production of new energy vehicles can not be separated from batteries, whether lead-acid batteries or three-yuan lithium batteries have a great demand for non-ferrous metals. From charging piles to new energy vehicles, and then to new energy batteries, the improvement of charging pile facilities will boost the development of the entire new energy vehicle industry chain from the bottom, and then the demand for lithium, lead, cobalt, nickel and other metals in new energy batteries will also increase.

5. Big Data Center, Artificial Intelligence, Industrial Internet

In addition to the above four areas, the other areas are big data center, artificial intelligence, industrial Internet. According to the forecast of Guangfa Securities, it is expected that in 2020 IDC related industry market scale will reach about 160 billion yuan; The core industry scale of artificial intelligence industry is expected to reach at least 500 billion yuan in 2020; The industrial Internet market will reach at least about 520 billion yuan.

The industrial scale of these three sectors is expected to reach about 1.2 trillion yuan in 2020, with capex accounting for about 10% of revenue.The investment scale in these three fields is about 120 billion yuan. Because these industries belong to the new high-tech field, the demand for non-ferrous metals is not large, only in some electronic components and packaging will use copper or aluminum and other metals, so do not repeat here.

6.summary

Overall, the investment scale of the seven new infrastructure sectors is expected to reach 1.1 trillion yuan in 2020, only accounting for 14.5% of the planned investment of 7.6 trillion yuan in 2020, and traditional infrastructure projects are still dominant. The new infrastructure is still in its infancy in terms of the scale of investment, but the industrial chain related to the seven sectors will be huge if extended, and the economic boost and energy efficiency generated will be huge. The ultimate goal of new infrastructure is to create new pillars of future industrial growth, create a new investment environment, and foster new consumption, whether it is the construction of transportation energy such as high-speed rail, subway, ultra-high voltage, or the construction of next-generation information infrastructure such as 5G networks, data centers, artificial intelligence, and industrial Internet.

The investment in new infrastructure is relatively small, and the consumption of non-ferrous metals such as copper and aluminum is not large. Meanwhile, the construction cycle of high-speed rail and ultra-high voltage projects generally takes many years, and the investment of the projects is carried out in stages. Therefore, the impetus of new infrastructure for non-ferrous metal consumption in 2020 is expected to be limited. Only the uHV part is expected to promote the consumption of more than one million tons of aluminum, more than 200,000 tons of copper, and less than 100,000 tons of zinc. The demand for non-ferrous metals in other new infrastructure projects is limited.

But from the perspective of the relevant industrial chain, the rapid development of new infrastructure is expected to drive the reform and upgrading of other related industries. For example, the charging pile industry can drive the consumption of new energy vehicles and new energy batteries from the bottom up, so as to promote the development of the whole new energy industry chain. The production of these industries requires a large number of non-ferrous metals. In addition, the construction of 5G base station will drive the development of the entire Internet. In the future, telemedicine, industrial control, remote driving, smart city, smart home and other applications are expected to step into people's lives. For non-ferrous metals, the most direct drive is the development of Copper cladding industry in China. The construction of 5G base stations has driven the upgrading of domestic copper foil technology, which will objectively promote the development of copper alloy material processing industry to the advanced direction.

陕公网安备 61019002002481号

陕公网安备 61019002002481号